AAA Industries is a well-known manufacturer of high-volume precision-turned machined parts and components through multi-spindle screw machining. We specialize in threaded fastener manufacturing, enabling us to produce small parts with intricate designs and complex geometries.

Regardless of your project’s requirements, we can produce numerous products, such as specialty fastener solutions, designed to improve your bottom line. Our state-of-the-art in-house screw machine shops enable us to engineer and develop products manufactured to the highest industry standards.

The Screw Machining Process

Screw machining refers to shaving a workpiece using a rapidly spinning lathe until the desired size is accomplished. These machines are available in single or multi-spindle and can be fed with up to 5 ft. bars in square, round, or hexagonal shapes. It’s equipped with automated tools for drilling, milling, threading, burnishing, thread rolling, taping, facing, cutting, shaving, broaching, reaming, slotting, knurling, and grooving, which makes the bar spin as the tools come in contact with them.

To achieve precision-turned parts and components, we utilize multi-spindle screw machining as our primary capability. Using cost effective multi-spindle screw machines, we can manufacture products that are typically cylindrical and threaded. Threaded fastener manufacturing is done in a screw machine shop, which is equipped with all equipment, tools, and devices necessary to do the precision screw machining process.

Some of the most common screw machining procedures include:

- Knurling: The knurling method generates a patterned texture to a metal surface to improve grip.

- Threading rolling and forming: Screw heads are mainly produced through thread rolling and forming. This procedure involves using a shaped die to apply pressure on a workpiece.

- Turning: The turning process commonly uses a non-rotary tool bit that moves in a helical toolpath. It’s utilized to create the exterior surfaces of a product.

- Rotary broaching: Rotary broaching is a technique that’s fast and can be done in seconds. It’s mainly used to create internal polygon structures accurately.

We can machine parts and components using a combination of the processes above. For specialty or standard fasteners, we’re capable of producing precise features using multi-spindle screw machining. Due to its consistent results, numerous industries rely on it for their demanding projects. These sectors include military, pharmaceutical, medical, aerospace, and automotive applications.

Products Produced Through Multi-Spindle Screw Machining

Advanced technology and innovative techniques enable us to fabricate a variety of specialized products through multi-spindle screw machining.

As aforementioned, many industries can benefit from screw machining, especially if they aim for higher-quality results. Apart from screws, it can support many vital products, such as medical devices, laboratory tools, electronic components, appliance components, and automotive parts, to name a few.

More examples of parts created through multi-spindle screw machining are as follows:

- Implant fittings

- Custom and specialty fastener parts

- Keyways

- Tire gauges

- Threaded knots

- Spindles

- Splines

- Spacers

- Standoffs

- Fittings

- Custom precision parts

Whether you require specialty or custom parts, AAA Industries can meet your exact specifications while exceeding your expectations. We have experience manufacturing the parts listed above, so you can trust us to deliver optimal results each time.

Screw Machining Materials Used

In multi-spindle screw machining, an extensive range of materials are utilized. However, it highly depends on a part’s specific function. That said, the most frequently used materials are aluminum, stainless steel, steel, titanium, and brass because of their properties. Learn more about these materials below:

- Aluminum: Predominantly known for its high ductility and incredible corrosion resistance, aluminum is primarily used in transportation, aircraft manufacturing, and construction. It’s also low in density and nonmagnetic, making it an ideal solution for lightweight and electromagnetic shielding applications.

- Brass: Copper and zinc make up most of the brass alloy. This material has outstanding workability, low friction, and extreme durability, with non sparking features. Examples of products made with brass are washers, injectors, bolts, and nuts.

- Steel: Iron and carbon are the main elements in steel alloy, giving it its high tensile strength.

- Stainless steel: One of the strongest steel alloys is stainless steel. It’s famous for its corrosion and stain-resistant properties, as well as being very robust. Stainless steel is also easy to sanitize and is fundamentally used to manufacture medical devices.

Apart from the materials listed, we can work with other metals as long as they’re machinable and depending on your project’s requirements. Our team of experts is well-versed in choosing the suitable material for the job to ensure high-quality and precise results.

Multi-Spindle Screw Machines at AAA Industries

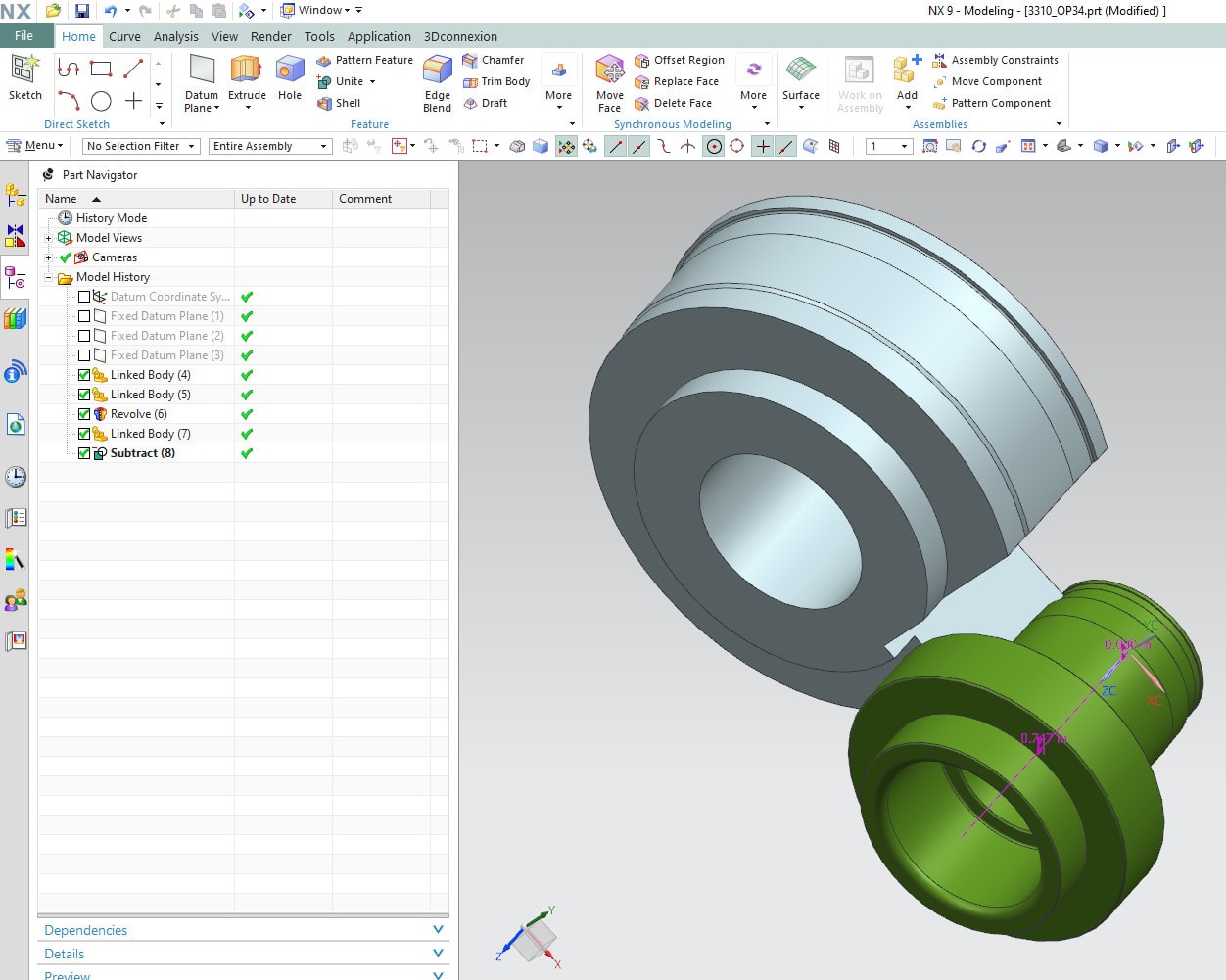

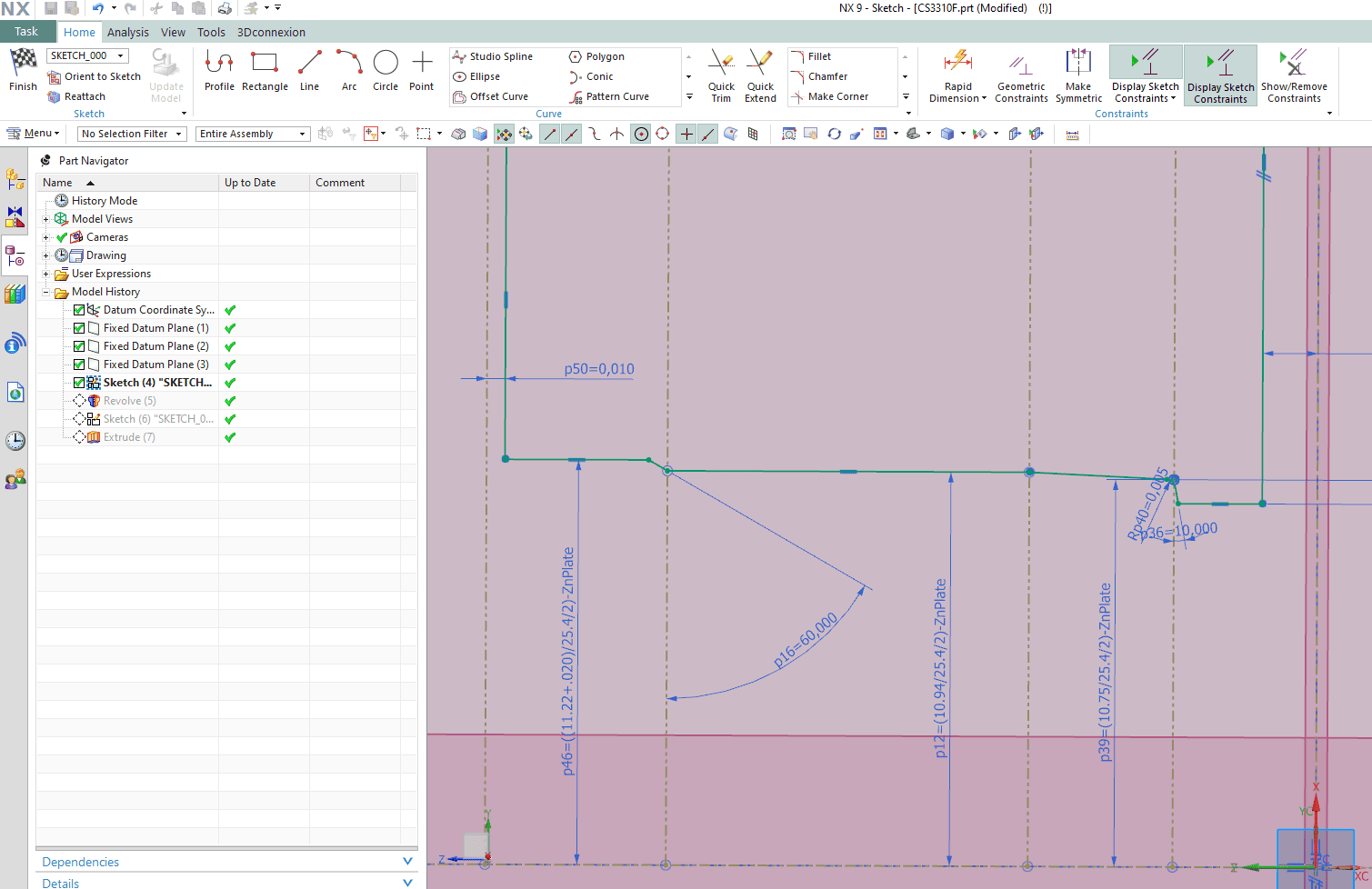

We employ high-volume Model B Davenport multi-spindle screw machines, which is an older style B machine with mechanical capabilities. Setting up these machines takes time since it relies on parts design, CAD design, and general system programming. However, it becomes surprisingly affordable and efficient when manufacturing large-scale, small, or specialty parts once the set-up is done.

Benefits of our multi-spindle screw machines include:

- Increased productivity due to larger capacity

- Better energy efficiency

- Simultaneous operations and shorter cycle times

- Consistent and highly accurate results

- Additional value with cost-savings

- Higher production volumes

- Possibility of more complex designs and shapes

- Improved surface finishes

- A long list of machining operations

Premium quality output is promised due to the innovative capabilities of our multi-spindle screw machines. We specialize in medium to high-volume production, suitable for industries and applications with complex and intricate parts requirements.

Choose AAA Industries for Optimal Quality Outcomes

We have a stringent quality control process, ensuring all products we produce are manufactured based on your project’s prerequisites. Our screw machine shop is equipped to handle various industries, and we’re dedicated to providing exceptional threaded fastener manufacturing services at a competitive price.

If you want to learn more about our multi-spindle screw machining service, contact us today. Ready to kickstart your project? Request a quote, and our team can find a cost-effective solution tailored to the job’s specifications!